Mastering In-Mold Decorations: Methods, Trends, and Ideal Practices for Optimal Outcomes

In the realm of production, the art of in-mold decorations stands as an essential aspect of item layout and production. As sectors constantly look for innovative methods to boost visual charm and functionality, grasping the details of in-mold decors has actually emerged as an important ability. From choosing the appropriate materials to integrating cutting-edge design patterns, the trip towards accomplishing ideal lead to this domain is multifaceted. By delving right into the approaches, trends, and finest methods that underpin effective in-mold decoration processes, companies can open a world of possibilities that not only raise the visual attraction of their items yet also improve manufacturing performance and strengthen consumer interaction.

Product Choice

Material selection is an essential facet of understanding in-mold designs, as it directly impacts the quality and sturdiness of the end product. When choosing products for in-mold designs, it is necessary to think about elements such as compatibility with the molding process, the wanted visual result, and the environmental problems the item will face. Polycarbonate products like abs, polypropylene, and polycarbonate are commonly made use of for in-mold designs due to their versatility and capacity to accomplish intricate layouts. These materials offer exceptional moldability, allowing manufacturers to produce complex forms and patterns with precision.

Furthermore, the picked material must have good bond buildings to guarantee that the decor adheres securely to the substratum throughout the molding process. Bond in between the design and the product is essential for stopping delamination and ensuring lasting visual allure. In addition, materials with high warm resistance are liked for in-mold decors, especially for products that will be subjected to raised temperature levels throughout their lifecycle. By carefully selecting the suitable product for in-mold decors, suppliers can enhance the overall quality and sturdiness of their items, satisfying the assumptions of both customers and end-users.

Layout Technology

A crucial variable in progressing the area of in-mold designs is the continuous exploration and execution of layout advancement methods. Design innovation plays a crucial duty in boosting the aesthetic appeal, capability, and general high quality of products made utilizing in-mold decoration processes. By including ingenious design components, makers can distinguish their products in the marketplace, draw in consumers, and remain ahead of competitors.

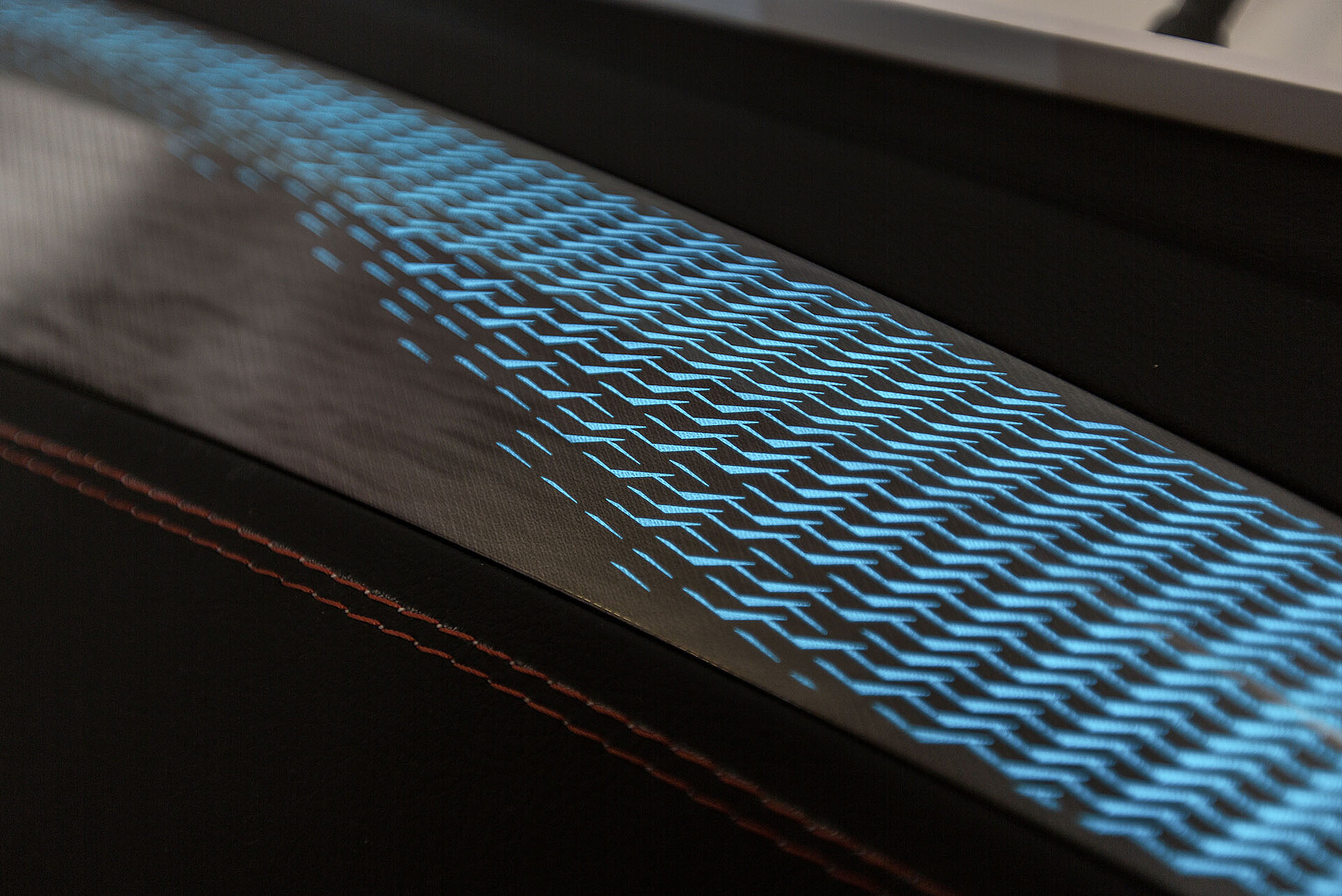

Among the crucial facets of design advancement in in-mold decors is the assimilation of complex patterns, textures, and graphics that were formerly challenging to attain with conventional decoration techniques. Advanced technologies such as 3D printing and electronic design devices enable developers to create complicated and detailed styles that can be seamlessly moved onto shaped parts. In addition, using vibrant colors, metal finishes, and unique results like gloss or matte structures can better elevate the aesthetic allure of in-mold embellished items.

Furthermore, style technology extends beyond aesthetic appeals to incorporate functional improvements such as ergonomic forms, integrated functions, and adjustable components that cater to certain customer needs. By embracing website link style technology, manufacturers can unlock new opportunities for creative thinking, personalization, and product distinction in the affordable landscape of in-mold decors.

Production Efficiency

Effective production procedures are crucial for converting the ingenious designs created in the area of in-mold designs into high-grade completed products that fulfill market needs and consumer assumptions. In the realm of in-mold decorations, manufacturing effectiveness encompasses numerous essential aspects that add to the overall success of the production read the article process.

Additionally, carrying out automation and robotics in the production line can significantly enhance efficiency by simplifying repeated jobs and minimizing the margin of mistake. Automation not only accelerates the production procedure however additionally improves accuracy and repeatability, resulting in an extra uniform and high-grade end product. Embracing lean production principles, such as just-in-time inventory management and waste reduction approaches, can further improve manufacturing efficiency by reducing downtime and enhancing source utilization. In general, an all natural approach to production effectiveness is vital in taking full advantage of the possibility of in-mold decor techniques and achieving ideal lead to the affordable market landscape.

Quality Assurance Measures

What are the vital techniques for ensuring rigid quality control actions in the realm of in-mold decors? Quality control steps are paramount in in-mold design processes to make sure the production of top notch and flawless completed items.

Using innovative technologies such as computerized inspection systems can likewise boost the quality assurance procedure by providing precise and trusted information for analysis. These systems can discover blemishes that may be missed by hand-operated inspections, thus boosting total product high quality and uniformity.

Regular training and advancement programs for staff members associated with the in-mold decoration process can additionally contribute to maintaining high-quality criteria. By informing team on ideal techniques, quality expectations, and the value of focus to information, companies can foster a culture of high quality awareness throughout the company.

Customer Allure

To enhance the marketability of in-mold decoration products, understanding and catering to consumer preferences play an important role in identifying their charm and success. Consumer appeal in this contact form in-mold decorations is influenced by various factors, including design visual appeals, color choices, sturdiness, and general functionality. Consumers are increasingly looking for individualized and one-of-a-kind items that show their individuality and style. Therefore, providing customization options such as personalized layouts, shade variations, and textural elements can dramatically boost the charm of in-mold decoration items.

Verdict

In-mold decors use a flexible and efficient method to improve product aesthetics. Understanding in-mold decors needs a holistic approach that takes into consideration all elements of the manufacturing procedure to make sure success.

In the realm of production, the art of in-mold designs stands as a critical aspect of item design and manufacturing. Style development plays a crucial duty in improving the visual charm, functionality, and total high quality of items produced making use of in-mold design processes.One of the crucial aspects of layout development in in-mold decorations is the combination of intricate patterns, appearances, and graphics that were formerly testing to attain with conventional decoration approaches.Efficient manufacturing processes are crucial for equating the cutting-edge designs created in the field of in-mold designs right into premium ended up products that satisfy market needs and consumer assumptions. Supplying personalization alternatives such as customized styles, shade variations, and textural aspects can dramatically enhance the charm of in-mold decor items.

Comments on “Achieving Superior Do With In-Mold Decorations in Production”